Call: 07971460044

Epoxy Pu Flooring

MOQ : 1000 Square Foots

Epoxy Pu Flooring Specification

- Mixing Ratio

- As per manufacturer recommendations

- Finish Type

- Glossy/Satin/Matte as required

- Material

- Epoxy Polyurethane

- Chemical Resistance

- Good resistance to Acids, Alkalis, Oils, and Salts

- Color

- Grey, Green, Blue or as required

- Surface Finish

- Smooth, Glossy, Seamless

- Form

- Liquid Base

- Bond Strength

- High Adhesion to Concrete Surface

- Pot Life

- 30-40 Minutes at 27°C

- Curing Time

- 24-48 Hours

- Compressive Strength

- 60-80 N/mm² (Depending on System)

- Application Area

- Industrial Floors, Commercial Complexes, Warehouses

- Thickness

- 1mm to 5mm

- Packaging

- Component A + Component B (Standard Industry Packing)

- Slip Resistance

- Optional Anti-Skid Finishes Available

- Shelf Life

- 12 Months in Unopened Condition

- Abrasion Resistance

- Excellent

- Product Type

- EPOXY PU FLOORING

- Usage

- Industrial and Commercial Flooring

- VOC Content

- Low

- Drying Time

- 6-8 Hours (Surface Dry)

- Temperature Resistance

- Up to 70°C continuous exposure

Epoxy Pu Flooring Trade Information

- Minimum Order Quantity

- 1000 Square Foots

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Telegraphic Transfer (T/T)

- Supply Ability

- 100000 Square Foots Per Month

- Delivery Time

- 4 Days

- Main Domestic Market

- All India

About Epoxy Pu Flooring

Experience the hot-selling EPOXY PU FLOORING, an outstanding choice renowned for its sizzling durability and inestimable performance. This product offers excellent abrasion resistance, lofty compressive strength of 60-80 N/mm, and high adhesion to concrete, ensuring seamless, glossy or satin finishes. Its chemical resistance stands out against acids, alkalis, oils, and salts, with a robust shelf life of 12 months. Low VOC content and diverse finishes make it perfect for industrial and commercial projects. Choose from grey, green, blue, or custom colors to match your needsstock ready for quick shipment from India.

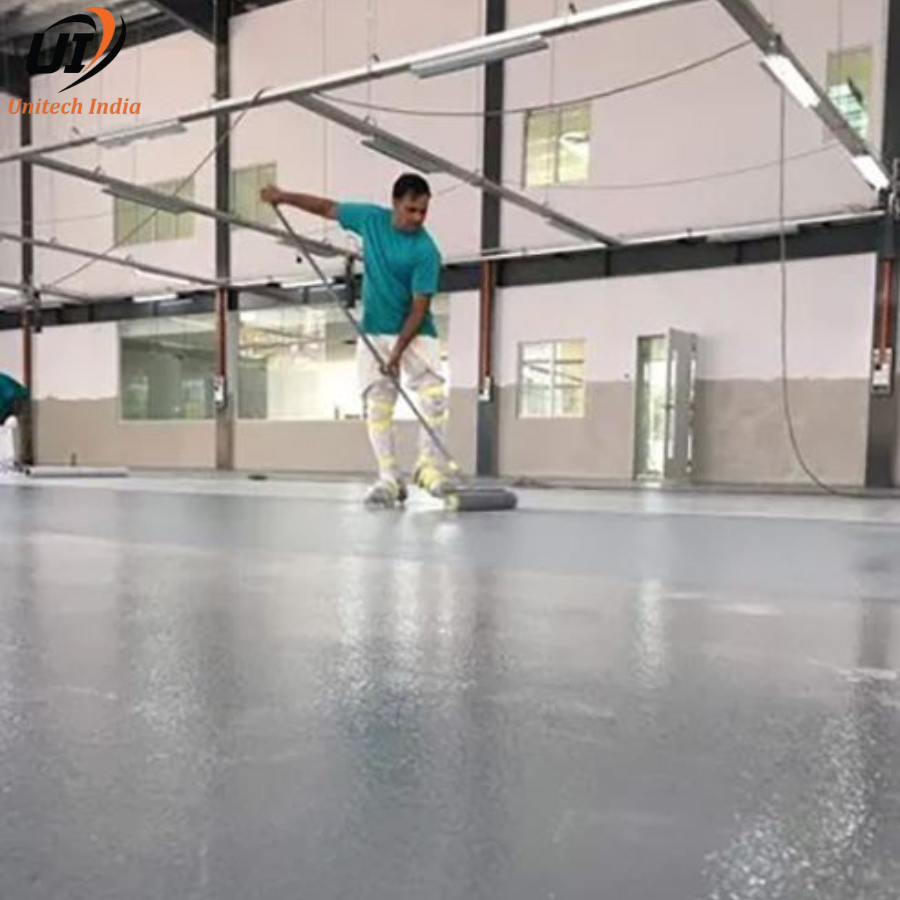

Versatile Application Areas & Impressive Features

EPOXY PU FLOORING is ideal for industrial floors, commercial complexes, and warehouses where high-performance standards are required. The products extra features include customizable slip resistance, temperature resistance up to 70C, and optional finishes from glossy to matte. Other salient features are its seamless, smooth surface and a choice of thickness ranging from 1mm to 5mm, making it adaptable for various usage needs with superior longevity and strength.

Sample Availability & Shipping Benefits

Obtain your EPOXY PU FLOORING sample todaystock ready for immediate demonstration. Shipments originate from a reliable FOB port in India, ensuring quick freight processing for both domestic and international orders. As a leading supplier, trader, and service provider, we ensure prompt shipment and support across the main domestic market, enabling you to witness firsthand the inestimable quality and performance before making bulk decisions.

Versatile Application Areas & Impressive Features

EPOXY PU FLOORING is ideal for industrial floors, commercial complexes, and warehouses where high-performance standards are required. The products extra features include customizable slip resistance, temperature resistance up to 70C, and optional finishes from glossy to matte. Other salient features are its seamless, smooth surface and a choice of thickness ranging from 1mm to 5mm, making it adaptable for various usage needs with superior longevity and strength.

Sample Availability & Shipping Benefits

Obtain your EPOXY PU FLOORING sample todaystock ready for immediate demonstration. Shipments originate from a reliable FOB port in India, ensuring quick freight processing for both domestic and international orders. As a leading supplier, trader, and service provider, we ensure prompt shipment and support across the main domestic market, enabling you to witness firsthand the inestimable quality and performance before making bulk decisions.

FAQs of EPOXY PU FLOORING:

Q: How does EPOXY PU FLOORING enhance abrasion resistance in industrial environments?

A: EPOXY PU FLOORING is engineered with hot-selling abrasion-resistant properties, ensuring a robust surface that withstands heavy foot and equipment traffic in industrial and commercial environments, minimizing wear and tear.Q: What is the typical process for installing EPOXY PU FLOORING?

A: The installation involves surface preparation, mixing Component A and B as per manufacturers recommendations, applying the liquid base, and allowing it to dry for 6-8 hours (surface dry) and cure for 24-48 hours, resulting in a seamless and durable finish.Q: Where can EPOXY PU FLOORING be primarily used?

A: This flooring is best suited for industrial floors, warehouses, and commercial complexes, providing a lofty solution for areas requiring exceptional strength, chemical resistance, and easy maintenance.Q: What are the key benefits of choosing EPOXY PU FLOORING over other flooring options?

A: Benefits include outstanding compressive and bond strength, customizable anti-skid or glossy finishes, good chemical resistance, low VOC content, and long-lasting seamless surfaces adaptable to multiple environments.Q: What is the available color range and finish options for EPOXY PU FLOORING?

A: Customers may choose from grey, green, blue, or customized colors, with a selection of finishes like glossy, satin, or matte to cater to any aesthetic or functional requirement.Q: When is the best time to order EPOXY PU FLOORING to ensure quick shipment?

A: Since the product is typically stock ready, placing orders aligned with project timelines allows for prompt processing and shipment via Indias FOB port, ensuring minimized freight delays.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pu Flooring Service Category

MOQ- 500 kg material & require warehouse of 2000 sq. ft.

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese